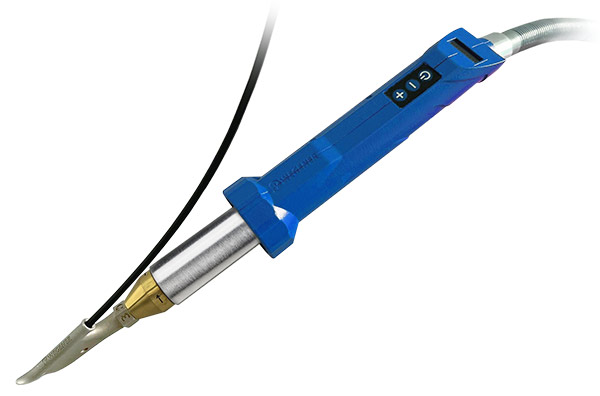

The new generation of Duratherm and Autotherm hot gas welding torches sets new standards in terms of ergonomics and performance.

Market launch of the EXWELD x4 extruder series with recipe management and full graphic display.

Market launch of the 8th generation of our butt welding machine SM. A novelty in quality and ease of operation.

Construction and opening of the extension building. On an area of 1000 m² there will be a showroom and a trainingcenter. Customers from all over the world can convince themselves there of the performance of the company and its products.

WEGENER presented the 3rd generation of the very successful EXWELD plastic welding extruders series. Furthermore we presented for the first time our new bending machine Type BM 306A.

Latest generation of WEGENER PBM Pipe Bending Machine successfully established in the market. The new stage of extension is able to process pipes of diameter 90 mm up to 315 mm in SDR-class 11 and 17. Other dimensions upon request.

WEGENER International would like to announce two innovations in the field of hot gas welding technology in Summer 2014. The Autotherm3 is a further development of the already established Autotherm device series and now represents the third generation of our hot gas welding tools. The control accuracy has improved with its convincing microprocessor controller in comparison to the second generation.

The Exotherm is the second innovation from Wegener. A newly developed self-supplied hot gas welding tool. This is evident with its innovative design and superior ergonomics. It is characterized by being lightweight, easy to handle and a particularly efficient and lightweight motor.

WEGENER International GmbH presents the SC range of compact welding machines. This fully-fledged welding machine offers the ideal requirements for welding of a quality that has only been known from larger welding machines to date for working widths from 1 to 2 metres on a compact footprint. The product portfolio has thus been consistently expanded to cover small working widths, without having to make any functional compromises with respect to the quality of the machine and weld seams.

Presentation of the new and compact EXWELD sigma2 series.

Move of the company into the new production plant in Eschweiler, Ernst-Abbe Strasse 30. On an areal of 7.000 square meters a modern and future proofed plant allows an effective production.

WEGENER International GmbH presents the newly developed STx25 butt-welding machine. This machine is available in lengths of 3 and 4 metres and the basic model already offers unrivalled value for money. The patented mechanical synchronisation of the working tables (WEGENER International patent) is just as much a part of the basic equipment as are the controlled proportional valves to apply the necessary process forces and the optional height-adjustable clamping beam.

WEGENER International GmbH takes over the business of WEGENER GmbH Messrs. Klaus-Peter Krügler and Dr. Reiner Weissfloch have retired for reasons of age. The new partners and managing directors are the long-standing executives of WEGENER GmbH, Messrs. Bernd Roßkampf and Michael Dietrich.

WEGENER develops the technology to seal corrugated sheets. This patent process is unique in sealing the edges of the corrugated sheets without damaging the outer layers. The control boards in our hot air welders are equipped with new micro controllers (flicker norm). This prevents negative electrical influence on other euqipment run on the same electric circuit.

The controllers for both butt welding and bending machines were changed to Siemens PLCs. This was the perfect opportunity to offer as well an optional industrial touch screen for easiest operation. The graphic interface of the screen is very similar to the former and very popular WEGENER controller. This makes the conversion from the older to the new style machines a snap.

we revolutionize drive technology in the field of butt-welding machines. By means of concurrent flow mechanics an extremely precise and secure concurrent flow of the machine tables is achieved.

In 1998 we set new benchmarks in extrusion welding technology. This type series provides our customers with highest welding performance at lowest weight.

the first fully automated, robot operated container production plant is commissioned./p>

our range of products is extended to the field of geosynthetic equipment. Since we provide a largely diversified program including heating wedge welding machines, testing devices and special extrusion welders for this market segment.

Die neue WEGENER-Extruder-Baureihe setzt Maßstäbe - der Absatz der Extruder steigt deutlich.

our welding machines become equipped with monitoring, closed loops. Further to reproducibility of the welding informative protocoling is now possible. Machines with force regulation (via DMS measuring cells) set a milestone in semi-finished product processing. In 1993 manual extrusion welders are the growth market. Our new type series sets a benchmark in the field of extrusion welding. Ever since the extruders are continuously enhanced and enjoy growing popularity.

In 1981 microelectronics find their way to machine construction and we establish our electronics department. Our own computer and controller development now enables us to act independent from component suppliers. From that time on we produce our tools and machines considerably more user friendly and operation and job oriented.

By introducing the first Teflon coated stainless steel heating elements in 1969 we raised the bar for quality in plastic processing even higher. Integrated in our first fully automated and relay controlled machines the user is now enabled for the first time to quality assured production. The complete equipment eliminates operation errors to the greatest possible extent. The reproducibility of the welding bending seams now provides the possibility for production with consistent and reliable quality.

For processing plastic sheets, for the first time used by the industry, we launch from 1959 to 1968 the first bending and butt welding machines as well as speed welding tips. The machines are equipped with infrared heating elements and are subject to continuous enhancement. The speed welding tips in combination with the first WEGENER hot gas welding tools; make sure that the users can operate with so far unknown quality, speed and perfection.

The WEGENER GmbH, arose in 1957 from a small engineering consultant for infrared technology. Within the following five decades the firm evolved into the only company worldwide to provide all tools and machinery for thermoplastic semi-finished products processing.

2025 - New generation of Duratherm and Autotherm

2022 - EXWELD x4-extruder with full graphic display

2017 - Opening of the extension building

2016 - 3rd generation of the EXWELD plastic welding extruders series

2015 - PBM Pipe Bending Machine

2014 - Autotherm3

2014 - Exotherm

2013 - Compact welding machines serie SC

2012 - The new Extruder EXWELD sigma2 SC

2011 - Move to Eschweiler

2009 - Butt-Welding Machine STx25

2008 - WEGENER International GmbH

2006 - User-friendly touchscreen

2001 - SM 440 – Butt Welding Machine with patented mechanical, synchronized parallel movement of the working tables

1998 - Exweld hydro with hydraulic drive

1968 - WEGENER Bending- and Butt Welding Automat

1959 - WEGENER Hot Air Welding Torch