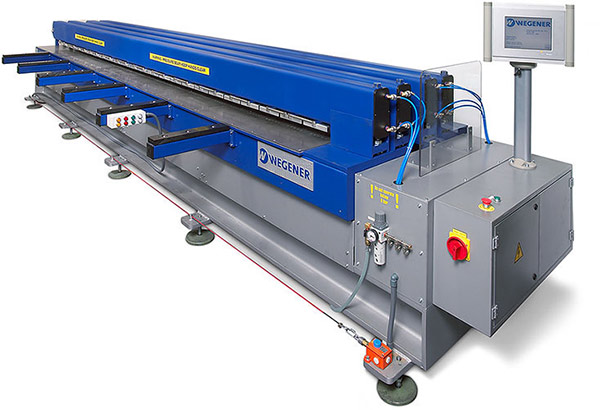

The all-rounder for the special application - for the processing of UHMW-PE for sheet thickness 3 up to 30 mm

Manufacture of reservoirs, tanks and containers, manufacture of plastic apparatus, pipeline construction, ventilation systems, serial welding, water treatment systems, scrubbers, environmental technology, swimming pools, transport and logistics

Patented mechanical, synchronized parallel movement of the working tables

Control system with 10 " full graphics touch screen

Tank construction

| Technical Data

|

SM 360

UHMWPE |

SM 460

UHMWPE |

SM 560

UHMWPE |

|---|---|---|---|

| Machine Length (mm) | 4,700 | 5,700 | 6,700 |

| Machine Width (mm) | 1,350 | 1,350 | 1,350 |

| Machine Height (mm) | 1,400 | 1,400 | 1,400 |

| Total Weight apporx. (kg) | 5,800 | 7,500 | 9,000 |

| max. Working Width (mm) | 3,050 | 4,050 | 5,100 |

| Sheet Thickness to be welded (mm): | 3 to 30 | 3 to 30 | 3 to 30 |

| PE (0.15 N/mm²) | 3 to 30 | 3 to 30 | 3 to 30 |

| PP (0.10 N/mm²) | 3 to 30 | 3 to 30 | 3 to 30 |

| PVDF (0.10 N/mm²) | 3 to 30 | 3 to 30 | 3 to 30 |

| PVC-C at 8 bar (0.5 N/mm²) | 3 to 30 | 3 to 30 | 3 to 30 |

| PVC-C at 10 bar (0.5 N/mm²) | 3 to 30 | 3 to 30 | 3 to 30 |

| PVC-U at 8 bar (0.6 N/mm²) | 3 to 30 | 3 to 30 | 3 to 30 |

| PVC-U at 10 bar (0.6 N/mm²) | 3 to 30 | 3 to 30 | 3 to 30 |

| PE 500 | 3 to 25

(1 N/mm²) |

3 to 25

(1 N/mm²) |

3 to 25

(1 N/mm²) |

| PE 1000 | 3 to 12.5

(2 N/mm²) |

3 to 12.5

(2 N/mm²) |

3 to 12.5

(2 N/mm²) |

| Power Supply | 230/400V

3/N/PE 50/60 Hz |

230/400V

3/N/PE 50/60 Hz |

230/400V

3/N/PE 50/60 Hz |

| Power Consumption (kW) | 3.5 | 4.5 | 5.5 |

| Compressed Air Connection (bar) | 10 | 10 | 10 |

| Clamping Force at 8.0 bar (kN) | |||

| Clamping Force at 10.0 bar (kN) | 150 | 200 | 250 |

| Welding Force: | |||

| Table Force min. (N) | 3,500 | 3,500 | 3,500 |

| Table Force max. at 10.0 bar (kN) | 78 | 104 | 129 |

| Heating Element

(teflon coated T max = 260° C) |

20 x 50 mm | 20 x 50 mm | 20 x 50 mm |

* bei der Option höhenverstellbare Spannbalken nur gültig in unterer Position der Spannbalken