The universal - fully-automatic bending and edging machine for sheet thicknesses from 3 up to 30 mm

Manufacture of reservoirs, tanks and containers, manufacture of plastic apparatus, ventilation systems, water treatment systems, scrubbers, environmental technology, swimming pools, transport and logistics

| Technical Data

|

BM x06A |

|---|---|

| Machine Length (mm) | 4,300 |

| Machine Width (mm) | 2,000 |

| Machine Height (mm) | 1,650 |

| Total Weight (kg) | 2,500 |

| Max. working width (mm) | 3,050 |

| Panel thickness (mm) | 3 to 30 |

| Min. bending angle | 5° |

| Max. bending angle | 95° |

| Min. channel cross section

with clamping beam: |

Inside dimension 175 x 175 mm

(assumes a square channel with four sides of equal length whose open end is closed by means of a if operated with clamping beam: downstream 90° weld) Inside Dimension 350 x 350 mm (when bending for welding outside the 4th edge, e.g. butt welds on a WEGENER butt welding machine). The min. channel cross-sections of the butt welding machine also have to be taken into account. |

| Min. channel cross-section

when using the vacuum clamping system option and residual clamping length reduction: |

Inside Dimension: 85 x 85 mm (remaining clamping length) |

| Min. remaining clamping length: | 175 mm (= remaining clamping length needed to clamp the panels in the machine; standard design)

85 mm with the vacuum clamping system option and residual clamping length reduction |

| Clamping force (at 8 bars in N): | 7,250 |

| Clamping areas: | 1 |

| Power Supply: | 230/400 V 3/N/PE, 50/60 HZ |

| Power Consumption (kW) | 7.5 |

| Compressed air connection (bar): | 8.0 |

| min. Restklemmlänge (mm) | 150 |

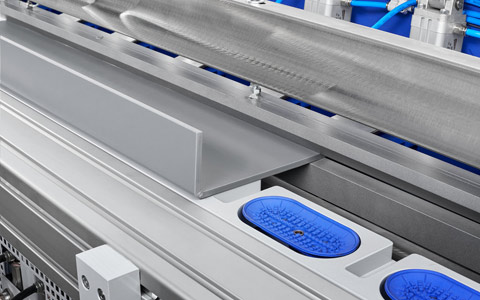

| Heating Element top

(teflon coated Tmax = 260° C) |

40 x 45 mm, 86° |

| Heating Element bottom

(teflon coated Tmax = 260° C) |

20 x 40 mm, blunt |